Converting CO2 Steyr Match 91 Running Target Rifle to air

Moderators: pilkguns, m1963, David Levene, Spencer, Richard H

Converting CO2 Steyr Match 91 Running Target Rifle to air

Has anyone converted their Steyr Running Target Rifle to air? If so, what parts are necessary?

-

Guest

Re: Converting CO2 Steyr Match 91 Running Target Rifle to ai

jrsmith wrote:Has anyone converted their Steyr Running Target Rifle to air? If so, what parts are necessary?

H!

Sorry to say but i would not recommend to upgrade the co2 rifle to air and for following reasons:

1. I will lower the rifles value when someone had fingered a ISSF competition rifle in such a scale.

2. Co2 has lower pressures in their system, therefore air has significantly higher pressure. You must change the whole valve system in theory to keep the gun safe and in competitive workin order.

3. There are no upgrade kits for this thing if you look for such

Regards,

RTarget

Owner of:

Single stroke pressured air RT rifle IZH 32 BK and pressured air RT rifle Walther LG300 RT

There is no kit that I know of for the Match 91, so there really is no reasonable way to convert it, with out doing lots of modification which from the sounds of it you do not have the expertise to do. I doubt that it would be feasible for you to convert it or have someone else do it for you. That said why would you want to convert it? I'm sure it will work just fine as a CO2 rifle.

You are correct. It works great. However, I have a large 5,000 psi tank that I use to fill my other air guns. It is more simplistic to fill air cylinders. No chilling of the cylinders before filling. I converted an LP5 to air. It was very simple. I was hoping for a similar conversion kit. It appears there are none available.

Rescently I bought such rifle exactly for conversion to air. A friend of mine do such job. Alredy he have a walther and a hammerli upgaded to air. Valve works perfectly in these conditions, rifle only need a new airtank and a regulator customly made for it. Main change of behavior of the rifle is increasing power of the rifle. Energy range can be regulated up to 16 joules without significant changes, that moves rifle among hi end FT rifles. Naturally energy can be regulated to 7.5 joules. In both cases this intervention resolve problem with missing CO2 tanks.

The key to this type of project is with the Steyr LP-1 CO2->CA conversion kit they sold. That kit includes air cylinders and a new pressure regulator to manage 3000 PSI vs 850 from CO2.

I did a Tau200 conversion... since it's a pretty inexpensive rifle and I was converting it into more of a field rifle, so I took the fast/cheap way out. I used a 13ci HPA tank (used in paintball) with a 800 psi Ninja regulator (used in paintball) on it.

Paintball guys have been converting CO2 guns to CA for a _long_ time. It's proven to work and it will be every bit -if not more accurate than the CO2 (depending upon the environment in which the CO2 was being used).

Anyway, my conversion works perfectly. And that TAU200 on CA is _extremely_ accurate.

Thread with pictures: http://www.targettalk.org/viewtopic.php?t=27721

Oz

I did a Tau200 conversion... since it's a pretty inexpensive rifle and I was converting it into more of a field rifle, so I took the fast/cheap way out. I used a 13ci HPA tank (used in paintball) with a 800 psi Ninja regulator (used in paintball) on it.

Paintball guys have been converting CO2 guns to CA for a _long_ time. It's proven to work and it will be every bit -if not more accurate than the CO2 (depending upon the environment in which the CO2 was being used).

Anyway, my conversion works perfectly. And that TAU200 on CA is _extremely_ accurate.

Thread with pictures: http://www.targettalk.org/viewtopic.php?t=27721

Oz

-

b2indurbs

converting CO2 Steyr match 91

I tend to agree with Oz:

from the start of the thread:

1- why would you expect higher pressures ?

- I believe anybody knowing a little bit about the difference about CO2 and PCP would know that CO2 runs around 70 bar of pressure - hence you'd need a regulator of some kind to reduce your 200/300 bar cartridge to that level. Without that its a no-go.

2- If it can be done with a pistol - why not with a rifle ?

There is enough information on the internet - e.g. see 'Schnorr Tellerfeder' which gives yo ua bisc calucation program for the springs and some Korrick designs. Together with some basic physics and a lathe - there is your regulator.

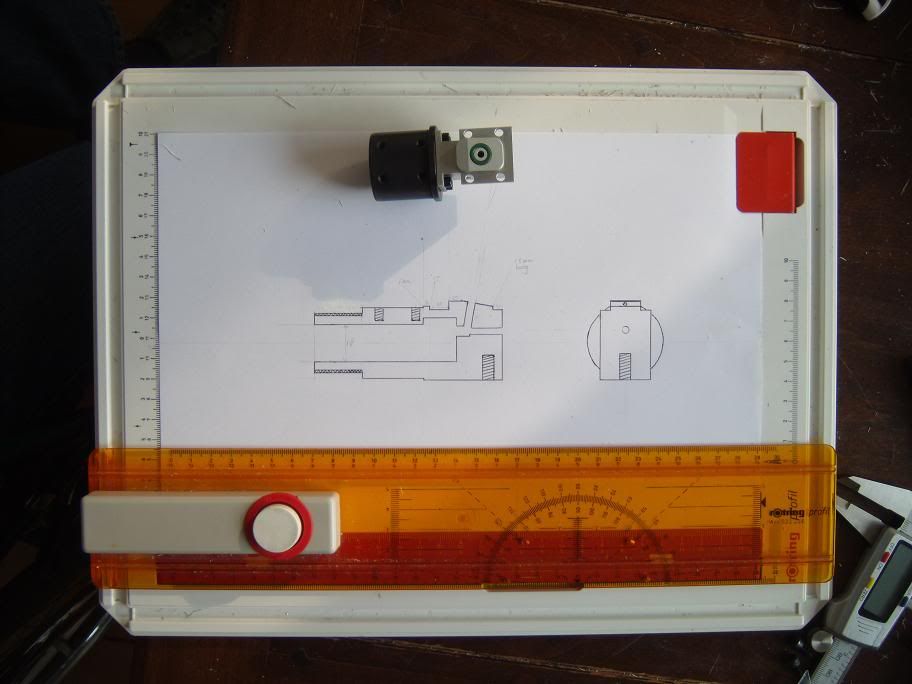

Not optimized though, but a start. Not for the beginner though, but there must be plenty of engineers out there, like me. Not owing one yet, but in the process. Once it is in my hands - what a nice project - drawings to follow for sure.

from the start of the thread:

1- why would you expect higher pressures ?

- I believe anybody knowing a little bit about the difference about CO2 and PCP would know that CO2 runs around 70 bar of pressure - hence you'd need a regulator of some kind to reduce your 200/300 bar cartridge to that level. Without that its a no-go.

2- If it can be done with a pistol - why not with a rifle ?

There is enough information on the internet - e.g. see 'Schnorr Tellerfeder' which gives yo ua bisc calucation program for the springs and some Korrick designs. Together with some basic physics and a lathe - there is your regulator.

Not optimized though, but a start. Not for the beginner though, but there must be plenty of engineers out there, like me. Not owing one yet, but in the process. Once it is in my hands - what a nice project - drawings to follow for sure.

-

ewoodie

Steyr match 91

Working on it. :-)

you need a new ( strong ) valvehouse from one piece to get some room for high pressure.

I try to get around 30 ft/lbs out of it.

with an Air Arms tube and an audruis regulator set at 150 Bar.

you need a new ( strong ) valvehouse from one piece to get some room for high pressure.

I try to get around 30 ft/lbs out of it.

with an Air Arms tube and an audruis regulator set at 150 Bar.

-

Sass

maybe a late answer but - is the conversion done?

To your drawings, I have 2 questions

1) How are you planning to machine the area right behind the valve? I is larger diameter than valve shaft hole so unable to machine from the right side and difficult to machine from left side. Unable to polish too.

2) How is the valve spring supported?

To your drawings, I have 2 questions

1) How are you planning to machine the area right behind the valve? I is larger diameter than valve shaft hole so unable to machine from the right side and difficult to machine from left side. Unable to polish too.

2) How is the valve spring supported?

-

Invictus87

- Posts: 24

- Joined: Sat Mar 30, 2013 8:10 pm

- Location: Southern Maine

Just about anything is possible if you have an EDM to burn it out. Lacking an EDM, I'd say go in with a boring head, then offset the boring head from the centerline of the bore opening to the left. Or, leave bore straight all the way back, drill through hole on right side down at an angle.

(I'm unfamiliar with what goes in these holes, just thinking of how I would go about machining a recess like that)

(I'm unfamiliar with what goes in these holes, just thinking of how I would go about machining a recess like that)